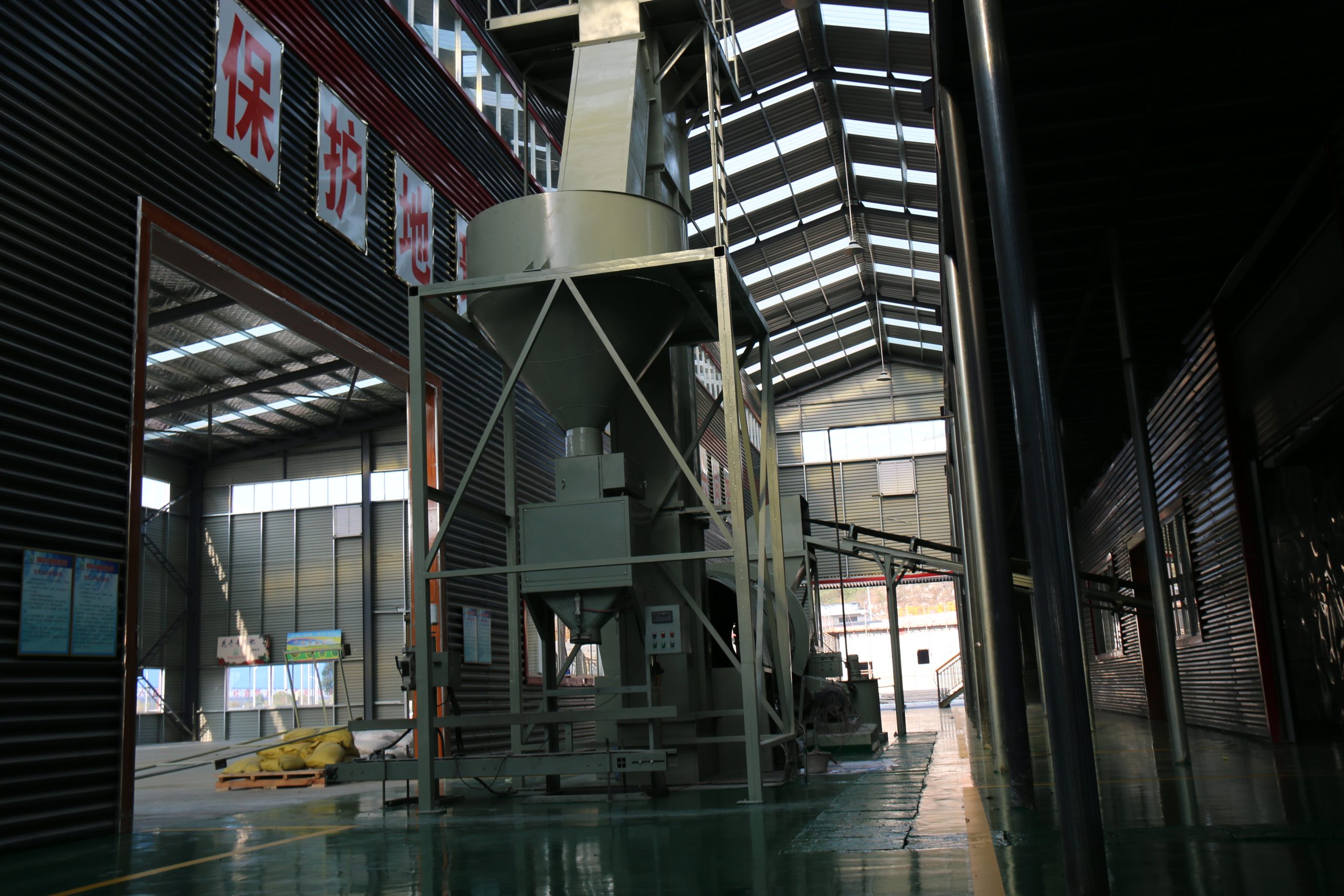

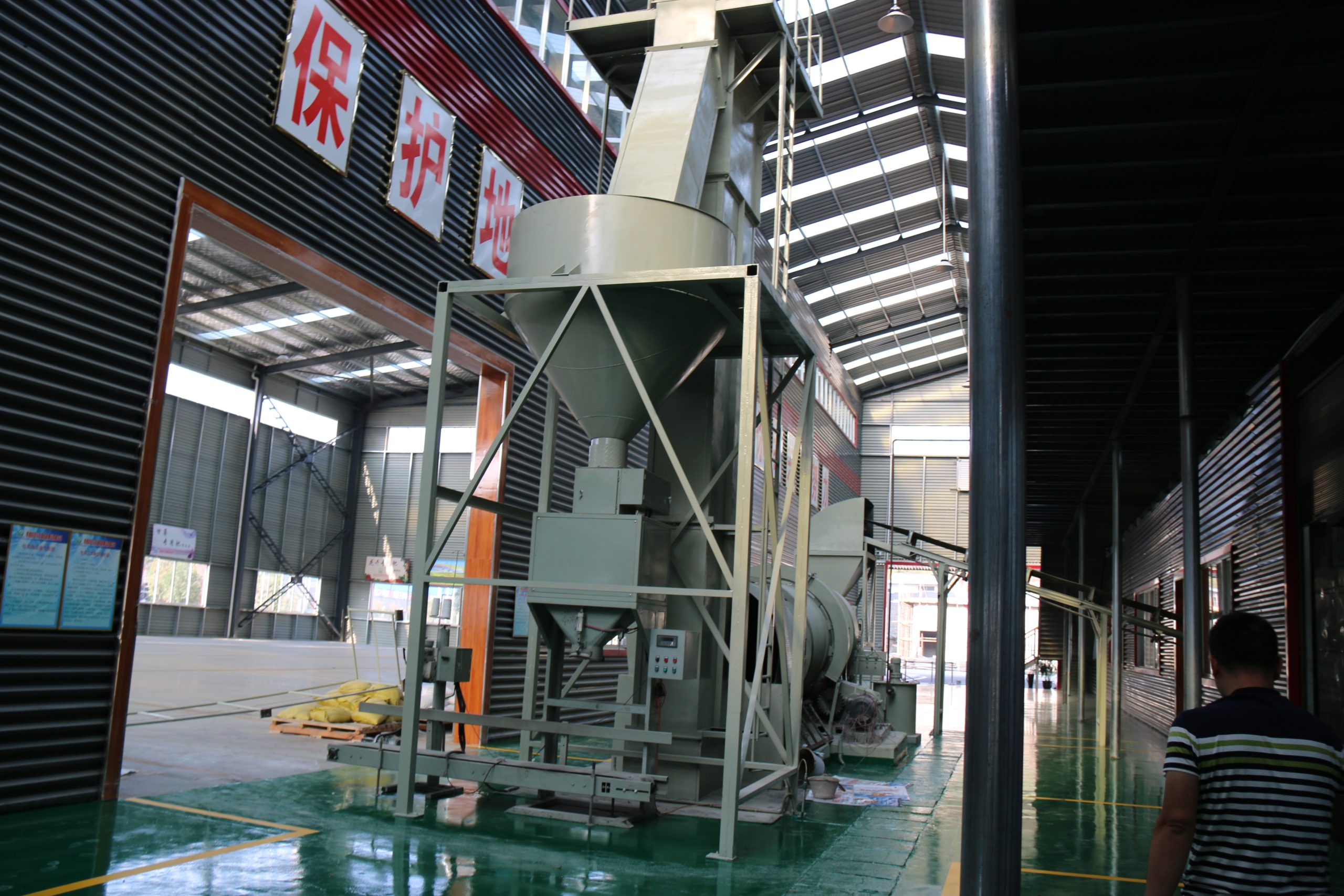

Coating Equipment

The working principle of the rotary coating machine is as follows: the material enters the rotary, and as the rotary rotates, the material is continuously coated, so that the particle surface is evenly coated with the material, and the material continues to roll forward in the rotary until it meets the coating requirements and is discharged from the discharge port.

The structure is composed of a cylinder, a wind head, a copying plate, a transmission device, and a tug rail.

| Purpose: | Used for particle surface coating of the compound, compound fertilizer, and organic fertilizer |

| Specification: | Ф1.4-2.2×5-10m |

| Production capacity: | 2~40t/h |

| Inclination angle: | 2.5° |

| 1. Structure description: the first zone is the oiling zone; the second zone is the powdering zone; the third zone is the mixing zone; and the fourth zone is the particle-enhanced polishing zone. Intermittent division to control material flow, built-in triangular copying plate 2. Supply instructions: Coating machine cylinder, rolling ring, large and small gears, transmission system, front and rear supporting wheel bases (including gear wheel device), gear cover, stirring tank, metering pump, pipelines, valves, equipment instruction manual, certificate. | |

What are the shipping ports?

A: Under normal circumstances, we ship from Shanghai, Tianjin, Qingdao, Ningbo ports, you can specify other ports according to your needs.

How about product pricing information?

A: Prices vary according to periodic changes in raw material prices.

My first time to import steel products, can you help me with it?

A: Of course, we have an agent to arrange the delivery, we will do it with you.

What product information do I need to provide?

A: Please kindly provide the grade, width, thickness, surface treatment requirement if you have and the quantities you need to buy.

Can you send samples?

A: Of course, we can provide customers with free samples and express shipping to all over the world.